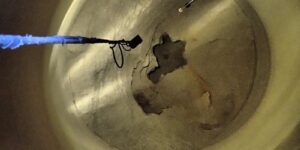

GIRONET, SILO AND HOPPER CLEANING SERVICE

SAM

5 December 2022POWERNET, INDUSTRIAL SILO CLEANING

6 December 2022

YOUR ANSWER FOR RATHOLING PROBLEMS

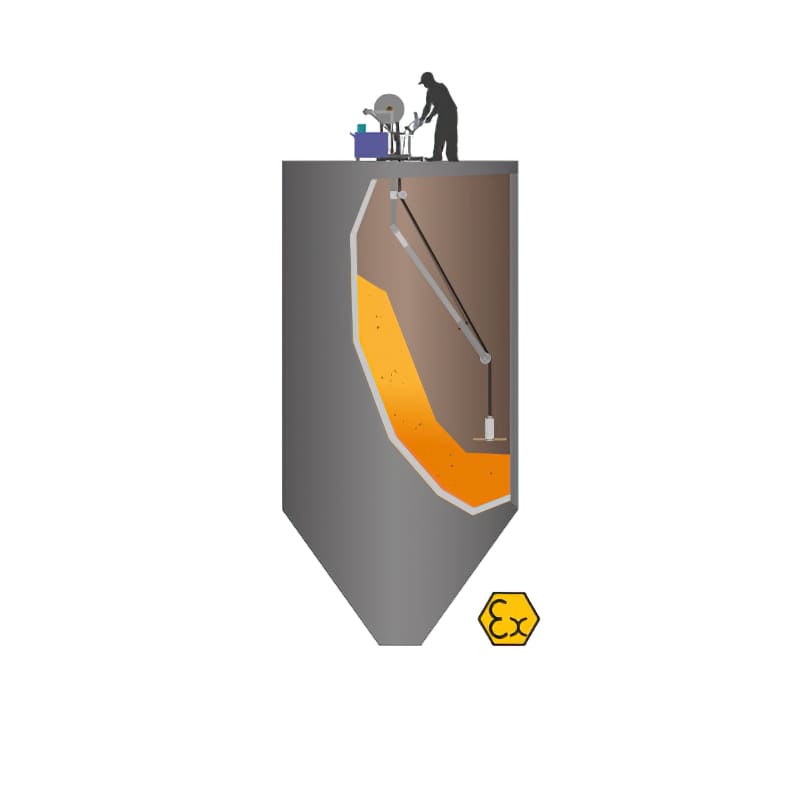

- 360° rotating hinged arm

- Intervention depth: Up to 45 m

- Controlled from outside

- All types of storage units

- All types of materials

- 3 versions :

- Pneumatic and ATEX Pneumatic for friable products (coal, bran, urea, ash etc.)

- Hydraulic : for hard products (slag, cement, clinker etc.)>

- TOTAL SAFETY: No human presence inside the silos and hoppers/Our teams comply with safety standards

- SAVINGS: Production continues while intervention/100% storage capacity regained/No loss of material

- PERFORMANCE: Intervention on all types of materials/rapid & efficient intervention

- Visits & recommendations

- Assembly & cleaning by us

- Rapid intervention

- Intervention by our specialised teams

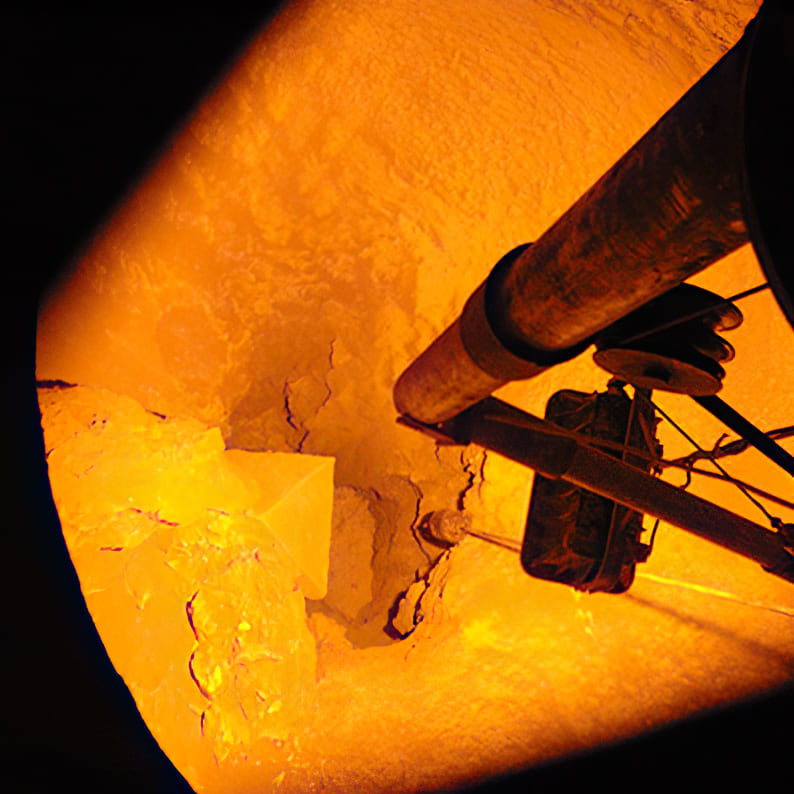

3 TYPES OF TOOLS:

- RISLAN brush: Use for thin layers of materials

- Stainless steel chains: Makes it possible to remove the material from the wall

- Brass chains: Makes it possible to remove explosive material from the wall (coal, sugar etc.)

Use of the GIRONET cleaning solution

- All

- Bran

- Sodium carbonate

- Sugar