INDUSTRIAL VACUUM CLEANING

9 June 2014SILO & HOPPER CLEANING SERVICES

9 June 2014

Our solutions

How to control dust within the operation or production site ?

Dusting is the presence of suspended or settled dust related to the operation and transformation processes in the plants. These dusts are likely to have consequences on the environment, on the operators within the plant and on the neighborhood.

Preventing the formation of pollutants at source is the most rational attitude to adopt, whether it be during the design and implementation of industrial processes or the construction of equipment.

For example, in quarries, the main dust emissions are diffuse and come from material extraction operated with machinery, or when those machineries drive on tracks. Fugitive dust can also originate from material storage, blasting or material conveying.

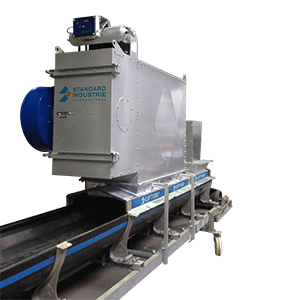

Covering rubber belts is necessary: it is a containment method adapted for some specific points, for example the protection of sand chutes, or to protect a conveyor when it is exposed to the wind.

Therefore the LIFTUBE® is real solution to contain dust in the industry.