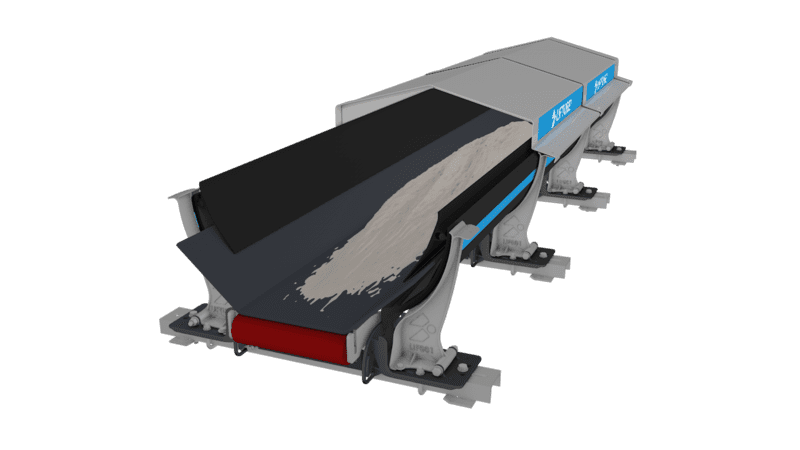

Declogging inside hoppers : the Airchoc® 6 solution is more economical

23 August 2023

Maintain flow of stored material

2 October 2023

the LIFTUBE® is one of the most efficient solution for problems of sealing

BULK INSIDE

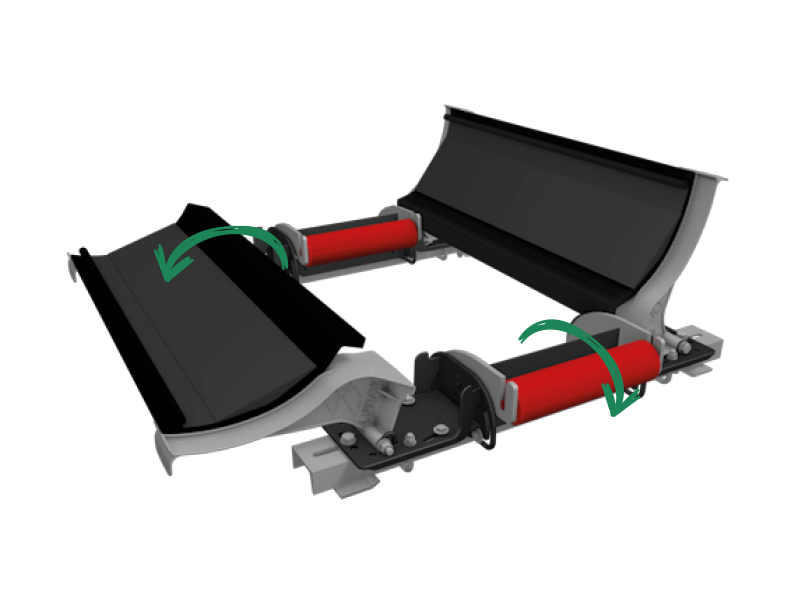

Optimizing production tools necessarily means reducing operating and maintenance costs. The LIFTUBE® system, developed and patented by STANDARD INDUSTRIE International, responds to this problematic by significantly improving the sealing of conveyor belts, improving the productivity and the safety compared to traditional conveyor belts.

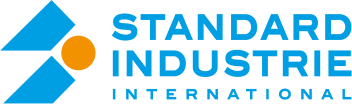

The LIFTUBE® is a solution that optimizes the sealing of any conveyor belt (smooth or cleats, rubber or PVC, hot or cold splicing) It comes as a replacement of stations equipped with 3 rollers on the conventional conveyors. These are standard 1-meter modules that are scalable and easy to install on all or part of a new or existing conveyor while keeping the belt, chassis, and motorization of origin. It is installed between the point of loading and unloading. Available in widths from 500 to 1400 mm, in high temperature, explosive, food or self-extinguishing versions, the LIFTUBE® avoids any contamination of the product transported with the outside environment.