WHAT BENEFITS DOES THE NEW VERSION OF THE AIRCHOC® AIR CANNON BRING?

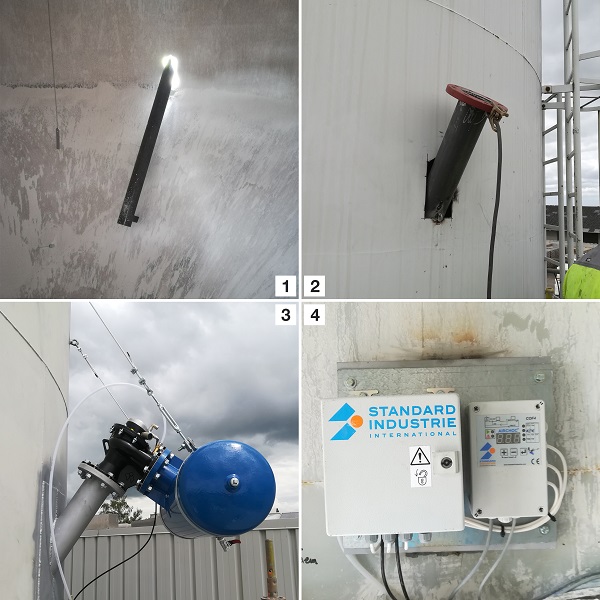

An air cannon has two main components: a pressure vessel (storing atmospheric pressure), and a release mechanism (high speed release of compressed air).

Air cannons are permanently installed on the walls of silos and hoppers for all powder-like materials, thus preventing the formation of bridging and ratholing while maximizing storage capacity.

Air cannons do not require a specific air pressure. The factory air supply is usually sufficient with a minimum pressure of 4 bar, although 5 to 6 bar provides better results. Average air consumption is moderate, depending on the number of shots per hour, the size of the tanks, and the number of air cannons installed.

The AIRCHOC® has always had the performance, profitability and safety characteristics expected by customers. The latest innovations of the AIRCHOC® version 6 are focused on compressed air savings.

Thanks to a better sealing of the piston and to a better impact force on clogging (10% higher than the older version), the air pressure can be reduced for an equivalent result.

The version 6 of The AIRCHOC® meets the challenges of the energy saving policy.

Using an AIRCHOC® air cannon makes it possible to stabilize and optimize the industrial processes. Indeed, when unclogging happens too late, this may cause a loss of material (solidified, for example), contamination or fermentation of products, or a temporary halt to production.