Air compressor

INDUSTRIAL CLEANING

5 April 2018THE MAINTENANCE OF OUR AIRCHOC® AIR CANNONS TANKS

5 April 2018

Operation, interest and uses ?

The choice of an air compressor is performed with respect to:

- The use of compressed air, but also its principles

- For its usage: motorisation, power, capacity, etc.

Two types of mechanisms exist in compressors, screw compressors and piston compressors. Both are suitable for professional and private compressors.

SCREW COMPRESSOR: THE MOST COMMON BUT THE MOST EXPENSIVE

The screw compressor is the most used system by the general public. Air compression is performed through the screw rotation of two rotors. On one side, the compressor sucks the air via screw rotation, on the other side, the air is released under pressure. The screw compressors’ small size makes them more convenient to use, especially for portable compressors or wireless compressors (example: inflating car tyres). They are also the most expensive in the market. Their high price can cause buyers to choose used compressors to reduce the bill.

PISTON COMPRESSOR: ESPECIALLY IN INDUSTRY, PARTICULARLY FOR GAS

Driven by a motor, the pistons move back and forth through cylinders equipped with non-return valves. It is this movement that creates the air compression.

Piston compressors are mainly used in the industry and can compress gases stably. (ABAC compressors for example).

The power supply motor type affects the operation and use of the compressors. There are two types of motors: electric or thermal.

ELECTRIC COMPRESSOR: THE SIMPLEST

The cheapest and most practical model to be used is the electric compressor. On the other hand, it cannot be used on a construction site. Indeed it must be permanently connected to a power supply.

The electric compressor is used for example for works on:

- Sandblasting: sandblasting gun

- Painting: airbrush and spray gun

- Inflating: blowgun via quick coupling

THERMAL COMPRESSOR: THE MODEL FOR PROFESSIONALS

Thermal compressor is especially intended for professional use. It derives its energy from fuel, gasoline or diesel. It is therefore more expensive than the electric compressor. On the other hand, it is much more powerful. Since it does not need a power outlet to start, it is much more mobile.

SPECIFIC COMPRESSORS: SILENT OR OIL-FREE

Compressors have their share of disadvantages. Some compressors have been designed to improve the quality of use of the devices and their comfort:

- Silent compressor: used in order not to disturb the neighbourhood but also to protect the hearing of users.

- Oil-free compressor: used in order to reduce waste and usage cost

SYSTEM SAFETY

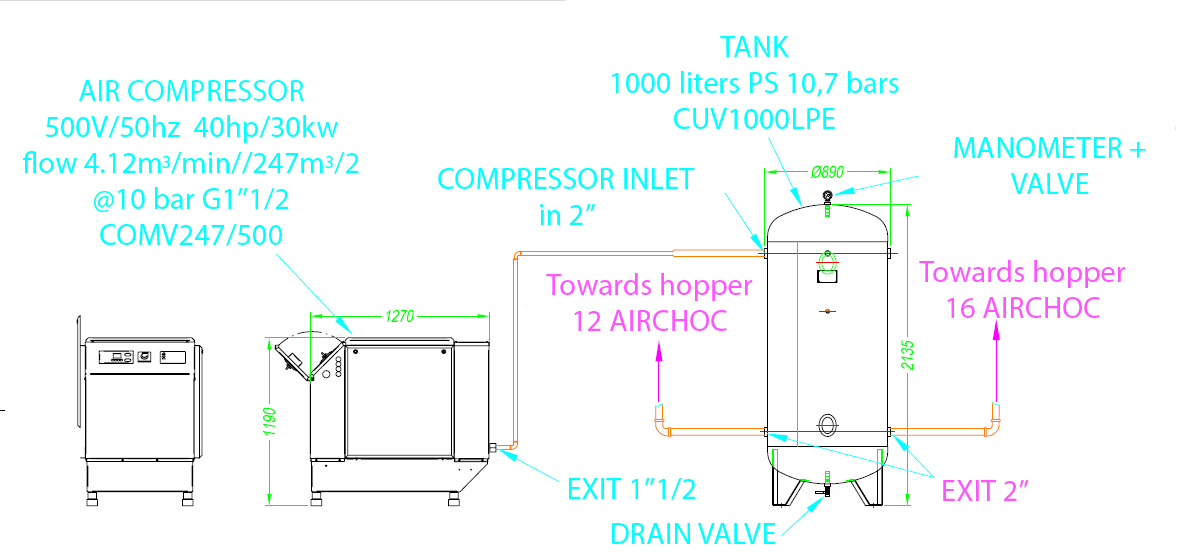

A reservoir/compressor tank may be dangerous because it is subject to high pressures. Fortunately, several systems allow the maintenance of optimal safety: manometer connected to a safety valve via a tee, drain valve, etc.

See the industry standard air compressor’s application

For the Standard Industrie International, compressors are an essential part of the cleaning and unclogging process of silos, hoppers, filters, etc. Compressed air is used, indeed:

- at the reservoir level of our Airchoc range of AIRCHOC® air cannons

- for our silo and hopper cleaning machines Gironet and our drilling machines Powernet

- also for our vacuum cleaning units (unclogging filters).

Our customers generally have in place compressor for the entire plant but we also have the opportunity to determine the power required for new installations and to set up new air networks to meet the requirements induced by our air cannons for instance.

The connection between the compressor and its reservoir is done via a rigid steel or stainless steel pipe, where the diameters can vary according to the desired power.

Below is an example of a compressor installation.